Our machines in action

Watch how our agricultural and civil engineering machines can enhance your daily operations in our videos.

Easycut Warzée

DE500 | Unroller-straw spreader Warzée

BB | Mixing bucket Warzée

Our Machines Designed for Agriculture and Livestock

Discover our complete range of agricultural and livestock equipment. Our agricultural machines with automatic hitch are designed to improve your productivity and simplify your daily work. Our equipment is robust, ergonomic, and adaptable to all types of machinery, from small farm loaders to the largest tractors.

Unrollers and Straw Spreaders

Our unrollers and straw spreaders with automatic hitch simplify the loading and distribution of round and square bales. You benefit from fast and uniform straw spreading and forage distribution for your livestock, without any effort.

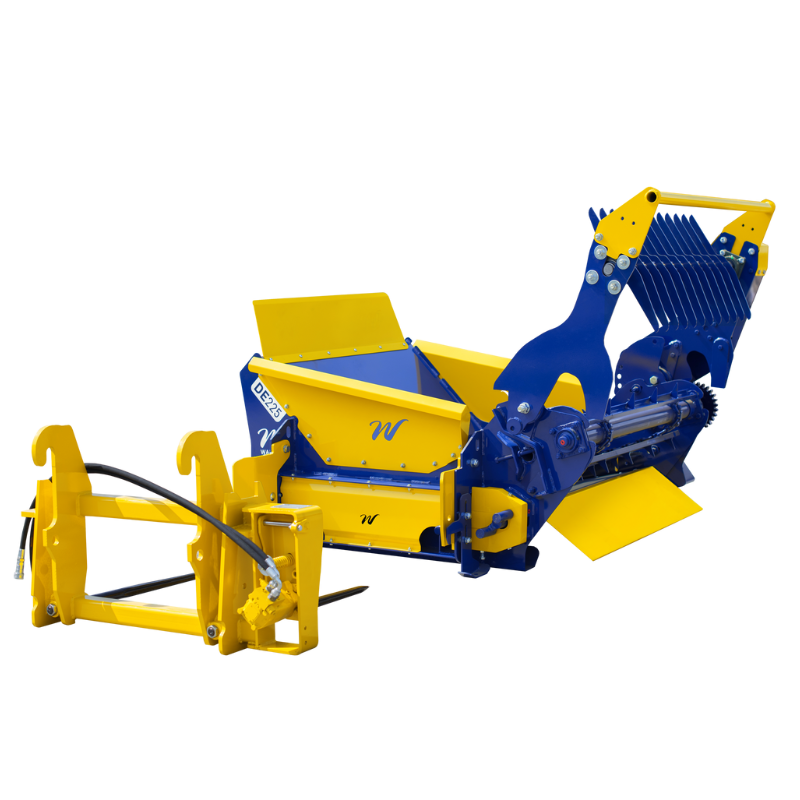

DE225 unroller

Compact round bale unroller

DE250 unroller

Round bale unroller

DE450R unroller

Round bale unroller

DE225 KP unroller – straw spreader

Round bale unroller + mulching kit

DE250 KP unroller – straw spreader

Round bale unroller + mulching kit

DE450RPH unroller – straw spreader

Dérouleuse à balles rondes + kit paillage

DE450RPM unroller – straw spreader

<span data-sheets-root="1">Round bale unroller + mulching kit</span>

DE500 unroller – straw spreader

Round bale unroller and round and square bale straw blower

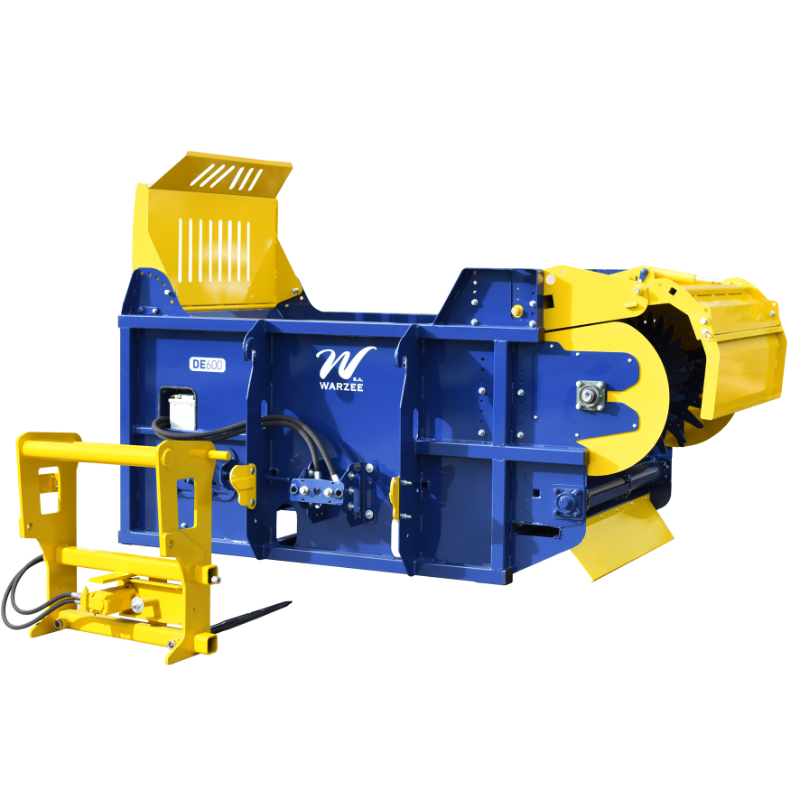

DE600 feeder – straw spreader

Square bale distributor and straw blower

Our Equipment for Civil Engineering and Green Spaces

We offer innovative and robust machines for professionals in civil engineering and green space maintenance. Our ergonomic solutions with automatic hitch adapt to the needs of your work sites, providing efficiency and safety on the ground.

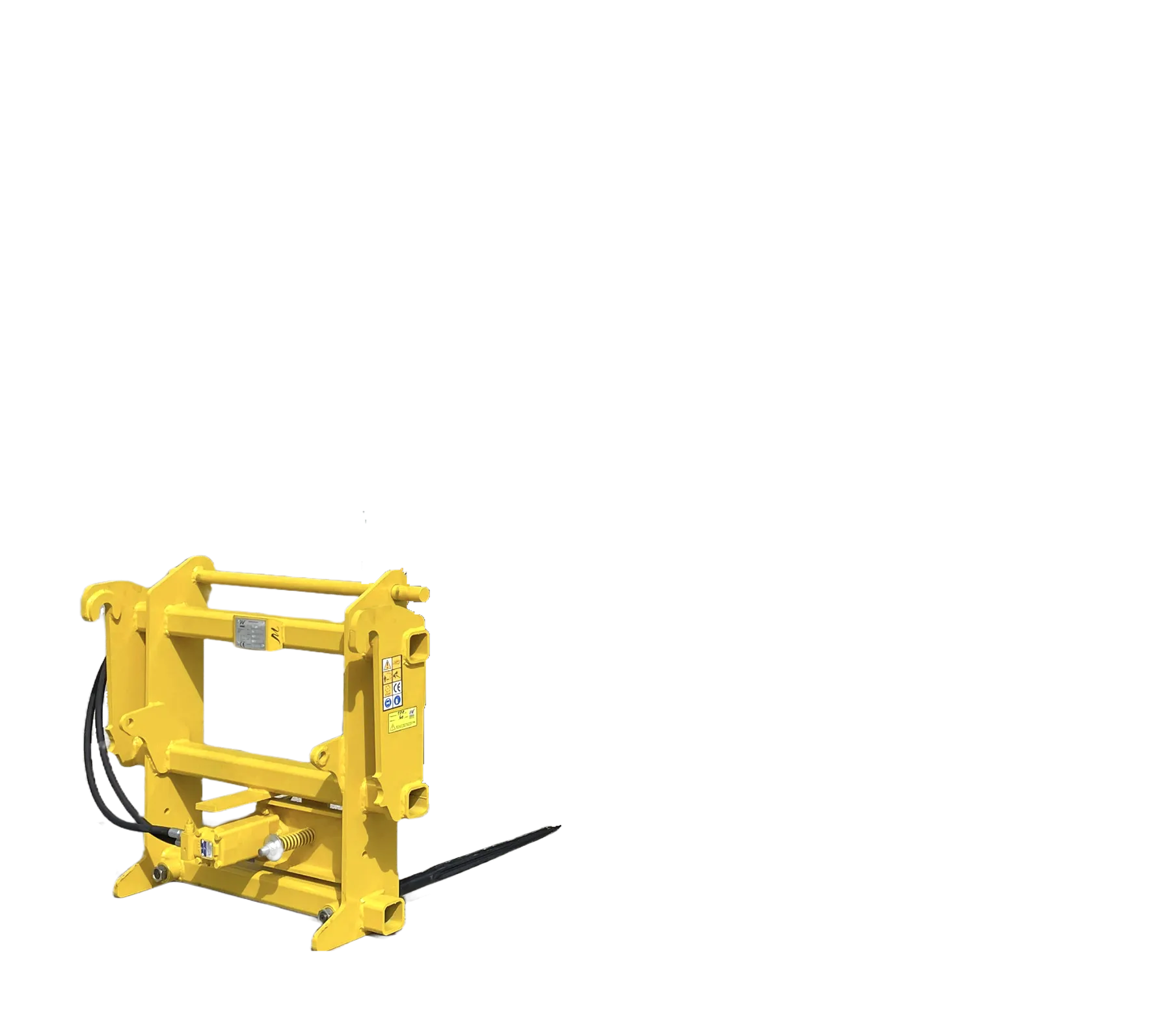

Mixing Buckets

Our mixing buckets with paddle mixing systems achieve a fast and homogeneous mix of all types of construction materials, whether dry or wet. They are designed to be robust and efficient, meeting the highest demands of the industry.

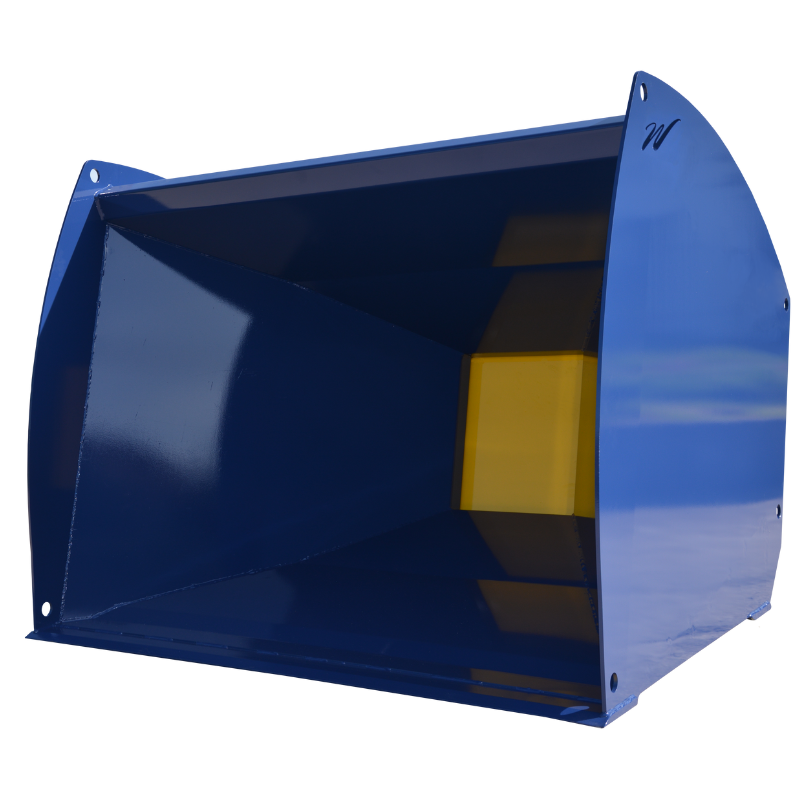

Bag filling bucket

750 to 2000 liters, big bag filler

BB150 mixing bucket

150 liters

BB210 mixing bucket

200 liters

BB290 mixing bucket

250 liters

BB410 mixing bucket

400 liters

BB610 mixing bucket

550 liters

BB1010 mixing bucket

1000 liters

BB1510 mixing bucket

1500 liters

BB2010 mixing bucket

2000 liters

Mini lean concrete plant

Fixed position mixing bucket

Warzée Innovation: the ConnectHyd Automatic Connector

Our innovation, the ConnectHyd automatic hydraulic connector, makes your work easier! This system can be installed directly on any vehicle (tractor, farm loader, etc.). With this technology, you can hitch different machines directly from the cabin without stepping out.

The connector attaches quickly, automatically, and safely to all equipped machines, without manual intervention. This allows you to switch between machines according to your needs, saving time and enhancing your efficiency and productivity in the field.

Warzée, designer and manufacturer of your machines

Founded over 30 years ago by Michel Warzée, our company designs and manufactures high-performance and innovative agricultural and construction machinery in Belgium. We develop ergonomic and robust solutions, designed by and for professionals, to perfectly meet their needs in the field. We control every aspect of production in our workshop in Hamois to ensure the impeccable quality of our equipment.

Our Company Values

Robustness

Our machines are designed to withstand the toughest working conditions in agriculture and civil engineering. We use high-quality materials like Hardox® steel to ensure their durability.

Innovation

With a continuous approach to innovation, we seek and develop new technical solutions to enhance the ergonomics and efficiency of our machines.

Experience

With over 30 years of experience in the field, we understand the needs of farmers and operators and develop machines that meet the demands of the agricultural and civil engineering sectors.

Sustainability

Committed to environmental protection, we power our workshop and production entirely with green energy generated by a biogas plant.

They chose Warzée

Find out why so many professionals in agriculture and civil engineering trust Warzée for their work machinery.

Become a dealer or importer of Warzée machines

To stay close to our customers, we sell our machines directly. However, to ensure local service for international clients, we are looking for dealers and importers of our equipment. Your role is crucial in helping professionals in the agricultural and civil engineering sectors benefit from our innovative and ergonomic machines. Interested? Let’s work together to make our technology accessible to everyone!

Want to join the Warzée team?

Are you looking for an exciting job in the design and construction of agricultural and civil engineering machinery? Do you want to work in the metal industry within a family-owned company in the Namur region? We’re hiring! Check out our job openings and join our dynamic team.

Our Latest News and Tips

Stay informed about the latest updates from our company and benefit from our best advice for the agricultural sector and civil engineering field.

Congés de mai

Nous vous informons que l’atelier Warzée sera exceptionnellement fermé aux dates suivantes du mois de mai : jeudi 1er et…

Warzée BR251R: Performance and simplicity for optimal cleaning

Optimisez l\'entretien de vos espaces avec la balayeuse BR251R Warzée Lorsqu\'il s\'agit d\'assurer la propreté, la balayeuse BR251R Warzée s\'impose…

Our DE225 unroller is 10 years old!

Celebrating 10 years of our Warzée DE225 unroller At Warzée, innovation is part of our DNA, and ten years ago,…

End-of-year holidays

End-of-year holidays at Warzée: A well-deserved break for our teams The year is coming to an end, and at Warzée,…

Latest innovation! Easycut Warzée

The new feature on the Warzée DE450R unrollers and Warzée DE500 unroller-straw spreaders We are unveiling our latest addition to…

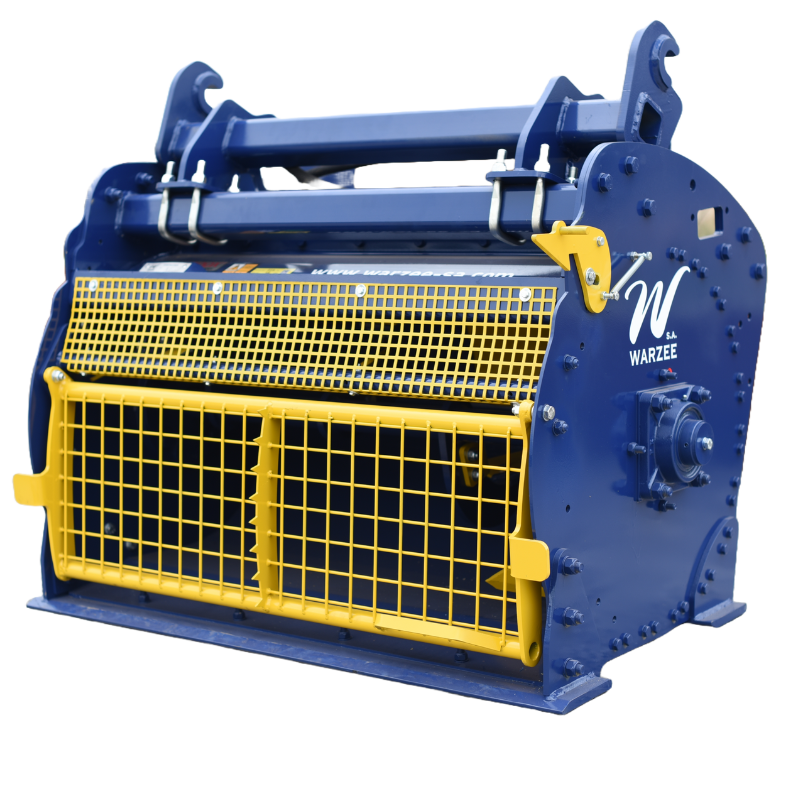

New! Removable screening grid

An innovation that revolutionizes bucket mixers with a removable screening grid At Warzée SA, we\'re always on the lookout for…